Comprehensive Oil Milling Solutions for Diverse Feedstocks

We provide end-to-end oil extraction systems tailored to the distinct properties of various raw materials. Our expertise covers a wide spectrum, including:

- Common Oilseeds: Soybeans, Sunflower Seeds, Peanuts, Canola/Rapeseed, Cottonseed

- Tropical/Tree Oils: Palm Kernels, Copra (Coconut)

- Specialty & Other Seeds: Sesame, Mustard, Castor, Flaxseed, Tea Seed

- By-Products: Corn Germ, Rice Bran

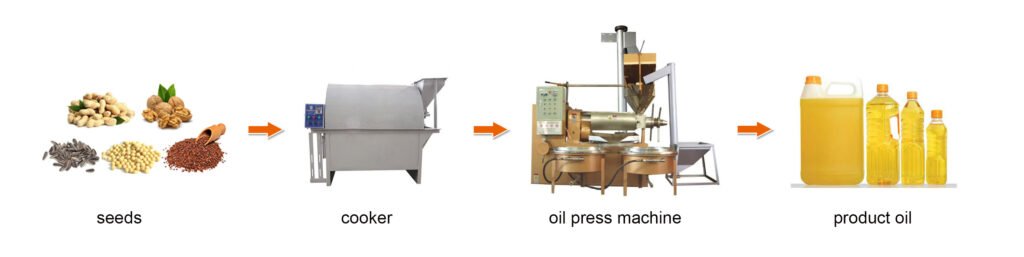

Small Oil Press Line

Medium & Large Scale Oil Production Plant

- Physical Pressing Method: Primarily used for high-oil-content seeds (e.g., peanut, sesame, rapeseed) or for oils where flavor retention is desired (e.g., olive oil, fragrant peanut oil).

- Flow: Oilseeds → Cleaning → Decortication/Dehulling → Crushing → Flaking → Cooking → Pressing → Crude Oil

- Characteristics: Lower oil yield, but the oil has a strong, rich flavor and retains more natural nutrients.

- Pre-press Solvent Extraction Method: This is the most mainstream and economical method for large-scale production, especially for low-oil-content seeds (e.g., soybean, rice bran).

- Flow: Oilseeds → Pre-treatment (Cleaning, Decortication, Flaking) → Pre-pressing (Extracts part of the oil, producing a cake) → Solvent Extraction (Soaking the cake in solvent, e.g., hexane, to dissolve remaining oil) → Miscella → Evaporation & Stripping to recover solvent → Crude Oil

- Characteristics: Very high oil yield, cost-effective, but the crude oil must be strictly refined to remove solvent residues.

| Oilseed Type | Oil Content (%) | Final Oil Yield (%) | Key Process Notes and Loss Reasons |

| Soybean | 18% – 22% | 16.5% – 18.5% | Soybeans are typically processed by Direct Solvent Extraction without pre-pressing due to low oil content. Yield depends on residual oil in meal (<1%) and moisture/impurities in beans. |

| Rapeseed/Canola | 35% – 45% | 38% – 42% | The industry standard. Pre-pressed cake (with ~15-18% oil) is solvent extracted to reduce final meal residue to <1%. Losses occur from meal fines and system retention. |

| Peanut (Kernel) | 45% – 55% | 44% – 50% | Dehulling is critical. High oil content allows for efficient pre-pressing, but material viscosity can lead to minor solvent extraction residues. |

| Cottonseed | 15% – 25% | 15% – 20% | Requires delinting and dehulling. Hulls constitute ~40% of weight; failing to remove them drastically reduces yield and increases solvent consumption. |

| Sunflower Seed (Kernel) | 45% – 50% | 43% – 48% | Dehulling is essential. Pressing with hulls absorbs significant oil, severely reducing yield. Efficiency is very high when processing kernels. |

| Rice Bran | 15% – 20% | 13% – 17% | Must be stabilized immediately after milling to deactivate lipase enzymes. Without fresh processing, rapid rancidity leads to high oil losses and poor quality. |

| Corn Germ | 30% – 35% | 29% – 33% | Germ is a by-product of corn milling. The purity of the germ impacts the effective oil content. This method provides stable and efficient extraction. |

| Flaxseed/Linseed | 35% – 45% | 36% – 42% | Seeds have a mucilaginous coat. Pre-conditioning must carefully control moisture and temperature to break structure for efficient oil release and solvent percolation. |

| Sesame Seed | 50% – 55% | 48% – 53% | While highly efficient, this method is less common for food-grade sesame oil, which is often pressed for flavor. The theoretical yield, however, is very high. |

| Camellia Seed | 40% – 50% (kernel) | 35% – 42% (on dry seed) | Dehulling is necessary. Traditional methods involving shells lead to lower yields. Advanced dehulling and this efficient process significantly improve recovery. |

- Refining Section:

- Degumming: Removes phospholipids and other gum-like impurities.

- Deacidification (Neutralization): Uses an alkali solution to neutralize free fatty acids.

- Bleaching: Uses bleaching clay (e.g., activated earth) to adsorb pigments, residual soaps, and trace metals.

- Deodorization: Uses high-temperature steam under high vacuum to distill off volatile compounds, off-flavors, and free fatty acids.

- (Optional) Winterization/Dewaxing: Cooling and filtration to remove waxes and saturated fats, preventing clouding or solidification at low temperatures. suitable for palm oil, sunflower seed oil, cotton seed oil……