Core Raw Materials for Fish Oil

High-quality fish oil typically comes from fresh, sustainable, small oily fish like anchovies.

Fish oil is primarily sourced from oily, cold-water fish:

- Key species: Anchovy (most common, balanced EPA/DHA), sardine/mackerel (rich in Omega-3s), herring (traditional Northern European source), plus tuna/salmon by-products (tuna oil high in DHA, salmon oil may have astaxanthin).

- Raw material types: Whole small oily fish (best for high-grade supplements, consistent quality) or fish processing by-products (sustainable/cost-effective, needs strict purification).

- Special case: Cod liver oil (from lean cod, high in natural Vitamins A and D).

Key factors: Freshness (prevents oxidation), sustainability (small fish have less heavy metals), purity (molecular distillation removes contaminants).

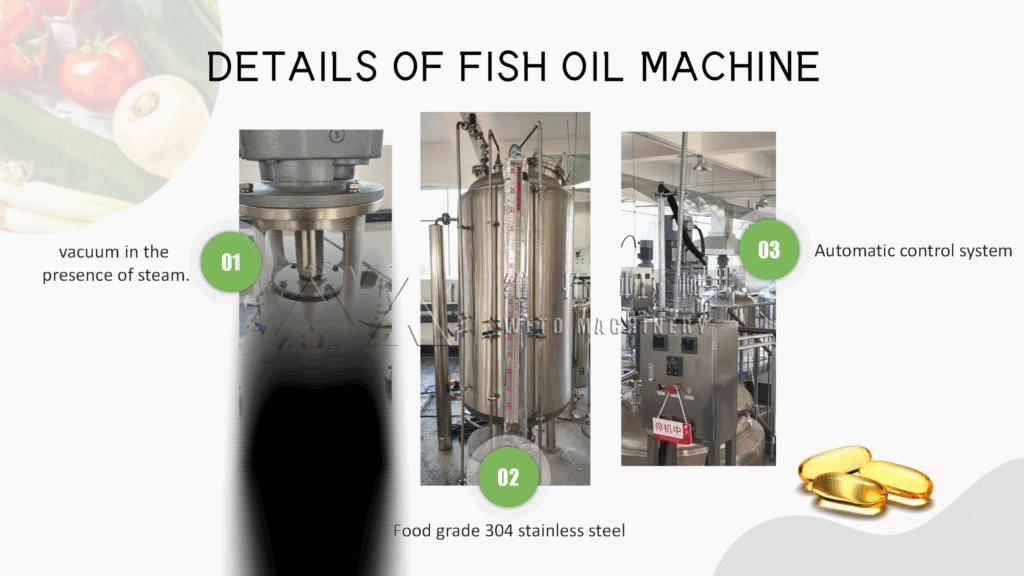

- Equipment material, food grade 304 stainless steel, easy to clean, clean seal lubrication, using food grade lubricating oil.

- Automatic control system, pure steam generator, thermal oil furnace.Electric heating.High pressure boiler for deodorization.The temperature is 180-190 degrees Celsius.

- The refining pot and soap corner pot are all sealed designs.The inner surface of the equipment is polished by mirror and the outer surface is brushed.The deodorizing part USES double Roots vacuum pump.

- Oil is easy to oxidize. After vacuuming, it can be produced by filling with nitrogen.The deodorized material is cooled with circulating water.

- If the oil quality is high, add light to remove the odor tower, and there is a grease trap to reduce splashing during deodorization, which will be taken away by vacuum.

- Aluminum or stainless steel for insulation.All tanks have several quick interfaces, connecting various pipelines, purification nozzle, nitrogen nozzle, vacuum nozzle.McIntosh vacuum gauge of 10 pa.The refining pan is made into a cone base.

- The heat conduction oil and cooling water of the deodorizing pan are built in coils.Argon arc welding.Internal polishing, external insulation.Heating and cooling of the deodorizer, an inner coil, a jacket, external insulation.

- .Add small plate and frame filter press.In addition, the cleaning device can not spare material, does not affect the normal production.Plate-type liquid level gauge is installed at the bottom of the cone to facilitate the observation of saponin.

- The bottom cleaning tube of deodorizing pan is perforated downward to prevent waste of residual oil inside.Jacket heating, inner coil cooling, jacket height should not be too high, less raw materials can be produced.The oil level should not be lower than the heating jacket.

- During deodorization, the oil foam catcher reduces oil spatter and prevents oil from being carried away by vacuum.

- Production process, closed production, packaging process, the whole process filled with nitrogen. Refining POTS and soap pans are all designed to be sealed.The inner surface of the equipment is polished by mirror and the outer surface is brushed.The deodorizing part USES double Roots vacuum pump.

- Several quick interfaces for all tanks, connecting various pipelines, purification ports, nitrogen ports and vacuum ports.McIntosh vacuum gauge of 10 pa.