The extraction of Crude Palm Oil (CPO) from Fresh Fruit Bunches (FFB) is a complex and integrated industrial process. The following is a detailed, step-by-step breakdown of the pressing and extraction stages.

FFB → shredder→Sterilization → Threshing → Digestion → Pressing → Clarification → Crude Palm Oil

1. Reception of Fresh Fruit Bunches (FFB)

- Purpose: To receive and prepare raw material for processing

- Process: FFBs are transported to the mill and weighed. They are then offloaded into loading ramps.

- Quality Control: Bunches are inspected for over-ripeness, under-ripeness, and excessive dirt. Immediate processing is crucial to prevent a rise in Free Fatty Acids (FFA) due to enzymatic activity.

2. Sterilization

- Purpose: To halt enzymatic degradation (which increases FFA), soften the fruit mesocarp, and loosen the fruits from the bunch. It also preconditions the nuts for later steps.

- Equipment: Large horizontal or vertical sterilizer vessels (cages).

- Process: FFBs are fed into the sterilizers. High-pressure steam (2.5 – 3.5 bar, 140°C) is injected for a defined time (60-90 minutes). The steam condenses on the bunches, heating them uniformly.

- Key Outcome: Fruits are easily detached from the bunch, and lipase enzymes are deactivated.

3. Threshing (Stripping)

- Purpose: To separate the sterilized fruits (palm fruitlets) from the empty fruit bunches (EFB).

- Equipment: Rotary drum thresher or beater drum thresher.

- Process: The sterilized bunches are fed into the rotating drum. The impact from the rotating beats knocks the fruitlets off the bunch.

- Outputs:

- Loose fruitlets are conveyed to the next stage.

- Empty Fruit Bunches (EFB) are expelled as a by-product, often used as organic mulch or as fuel for the boiler.

4. Digestion (Mashing)

- Purpose: To break open the oil-bearing cells in the fruit’s mesocarp (flesh) and loosen the pericarp from the nuts. This creates a uniform mash or pulp.

- Equipment: A vertical or horizontal digester (a steam-heated vessel with stirring arms).

- Process: The loose fruitlets are heated (90-95°C) and continuously stirred by the rotating arms. This action ruptures the oil cells and separates the pulp from the nuts, forming a thick oil mash.

- Key Outcome: A homogeneous mixture of oil, water, pulp fibre, and nuts is formed, ready for extraction.

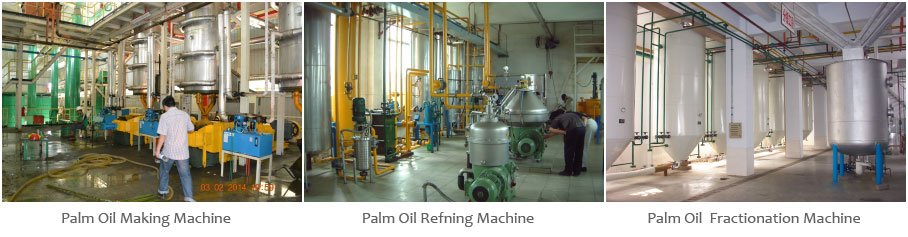

5. Pressing (Extraction)

- Purpose: To mechanically extract the crude palm oil from the digested mash.

- Equipment: Continuous screw presses (single or double cage presses).

- Process: The hot mash is fed into the press. A rotating screw conveyor pushes the mash through a perforated cylindrical cage. Increasing pressure along the length of the screw squeezes out the oil mixture.

- Outputs:

- Press Liquor: A mixture of crude oil, water, and fine solid impurities (cell debris). This is sent for clarification.

- Press Cake: A moist solid residue consisting of fibres and palm nuts. This cake is sent to the depericarper for nut/fibre separation.

6. Clarification and Purification

- Purpose: To separate the pure crude palm oil (CPO) from water and solid impurities in the press liquor.

- Process:

- Screening: The press liquor first passes through a vibrating screen or hydrocyclone to remove coarse solids.

- Settling Tank (Continuous Clarification Tank): The screened liquor is pumped into a large, heated tank where it is held for several hours. Oil, being lighter, rises to the top, while water and sludge settle at the bottom.

- Filter: After sedimentation, the oil enters the filter press for further purification to remove fine impurities.

- Vacuum Drying: The cleaned oil from the filter is passed through a vacuum dryer to remove any residual moisture (< 0.1%).

- Outputs:

- Crude Palm Oil (CPO): The main product, stored in tanks for shipment to refineries.

- Sludge: Sent to a recovery system to extract remaining oil. The final effluent is treated as Palm Oil Mill Effluent (POME).